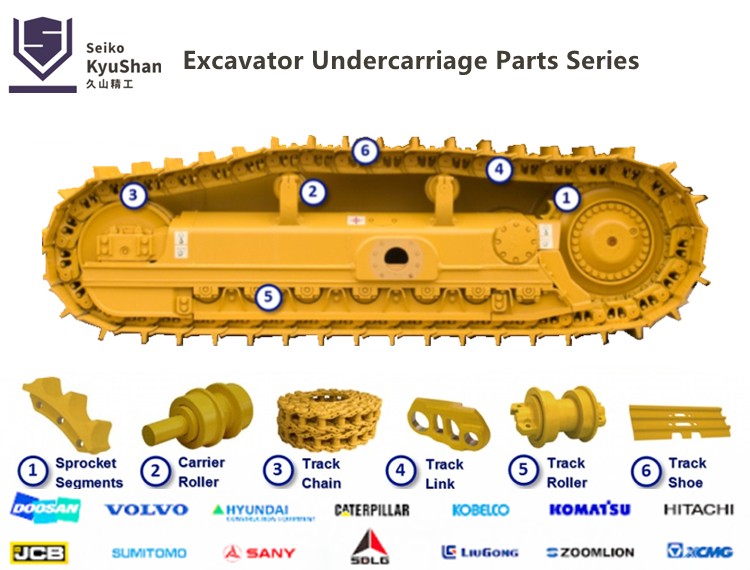

Key Parts: Undercarriage Components for Heavy Machinery

In the realm of heavy machinery, the undercarriage serves as an essential structure that makes certain the smooth procedure and durability of the equipment. Trick elements such as track shoes, rollers, idlers, sprockets, and track chains play a critical duty in the capability and efficiency of these enormous machines.

Track Footwear

Track shoes play an essential role in the efficiency and sturdiness of hefty equipment's undercarriage system. Track footwear come in numerous designs and materials to match different operating problems and surfaces.

The design of track shoes is engineered to supply optimal ground call, decreasing slippage and improving the device's ability to navigate challenging surfaces. Proper upkeep and routine examination of track footwear are necessary to stop premature wear and ensure the undercarriage system's long life. Any kind of signs of wear, such as irregular wear patterns or too much damages, need to be resolved without delay to stay clear of pricey repairs and downtime.

Rollers

Rollers are vital parts of the undercarriage system in hefty equipment, operating in conjunction with track shoes to guide the equipment and sustain's activity. These round steel components are tactically placed along the undercarriage framework and be available in different kinds such as provider rollers, track rollers, and idlers. Provider rollers aid in sustaining the weight of the devices, while track rollers assist disperse the lots and make certain smooth track footwear articulation (undercarriage parts). Idlers act as a tensioning mechanism for the track chain, preserving correct track stress for optimal performance.

To improve durability and efficiency, rollers are commonly created from top notch products like forged steel, offering resistance to wear and tear under heavy lots and harsh working conditions. Correct lubrication is important to minimize rubbing in between the rollers and track footwear, expanding the life-span of both parts. Routine evaluation and maintenance of rollers are important to protect against early wear and possible failures, ensuring the continual procedure of hefty machinery.

Idlers

Idlers play an essential role in the undercarriage system of heavy machinery, offering as vital parts for preserving proper track chain tension and making certain ideal device efficiency. Idlers are in charge of directing the track chain and sustaining the weight of the devices. These round rollers are strategically put along the track framework to disperse the device's weight uniformly, reduce vibration, and boost stability during procedure.

Properly operating idlers help prevent early endure the track chain and various check other undercarriage elements, ultimately extending the life-span of the equipment. They likewise add to sustain effectiveness by reducing moving resistance and reducing the energy called for to move the tools (undercarriage parts). Routine inspection and upkeep of idlers are necessary to discover any indicators of wear, misalignment, or damages that might lead to performance problems or downtime

Gears

Playing an important duty in the undercarriage system of hefty machinery, sprockets are crucial components responsible for transferring power from the equipment to the track chain. Sprockets include toothed wheels or equipments that fit together with the web links of the track chain, making it possible for the equipment to propel ahead or backwards. By recognizing the relevance of sprockets in the undercarriage system, operators and upkeep personnel can efficiently manage these parts to boost the total performance and integrity of hefty equipment.

Track Chains

An indispensable part of the undercarriage system in heavy machinery, track chains play an important role in assisting the activity and sustaining of the devices. Track informative post chains are durable metal chains that link the drive sprocket to the wheels or tracks of the hefty equipment. These chains are made to withstand immense tension, wear, and tension while ensuring smooth and reliable operation of the machinery.

Track chains are composed of private web links that are linked by pins and bushings. The design of track chains is crucial as it straight affects the total performance and resilience of the hefty machinery. Correct maintenance of track chains is necessary to avoid early wear, reduce downtime, and expand the life expectancy of the tools.

Regular assessments, lubrication, and adjustments are required to maintain track chains in ideal problem. Failure to preserve track chains can cause enhanced functional costs because of constant replacements and repair work. Consequently, buying top notch track chains and sticking to a strict maintenance timetable is crucial to optimizing the efficiency and durability of hefty equipment.

Verdict

In final thought, the key elements for heavy equipment undercarriage components consist of track shoes, rollers, idlers, sprockets, and track chains. These parts are necessary for the proper functioning and operation of heavy tools, giving grip, stability, and support. It is essential for operators and upkeep employees to routinely inspect and keep these components to guarantee the safety and efficiency of the machinery.

Key components such as track footwear, rollers, idlers, sprockets, and track chains play a crucial duty in the capability and efficiency of these huge equipments (undercarriage parts). Carrier rollers aid in great site sustaining the weight of the tools, while track rollers help disperse the tons and ensure smooth track footwear articulation. Idlers act as a tensioning device for the track chain, preserving proper track stress for optimal efficiency

Track chains are robust steel chains that link the drive gear to the wheels or tracks of the heavy equipment.In final thought, the vital elements for hefty equipment undercarriage components consist of track footwear, rollers, idlers, gears, and track chains.